CNC machines have several advantages compared to other machinery by boosting efficiency, precision, and reducing waste in your shop. Their versatility and accuracy make them valuable additions to multiple factories, and the applications for these machines are endless. Here are some of our favorite ways you can use CNC machines in a business.

Signs and Signage

CNC routers can skillfully work with an extensive array of materials, including wood, foam, acrylic, plastic, brass, aluminum, and much more. You can create a 2D sign that simply depicts your business’s name, or you can add a 3D component that the manufacturer and drill within the piece itself.

Machines with a vision system (which inspects and guides the robot along with the material) can quickly register a tool path when crafting carvings or signage. Many modern design shops use this technology to produce results such as braille, text, character spacing, and other various design elements to make the perfect sign.

If you want to create a sign for yourself, you can purchase a CNC machine at https://revelationmachinery.com/. Revolutionary Machinery buys and sells machinery.

Musical Instruments

You need absolute precision while making a musical instrument because a design element that doesn’t fit or warps slightly will completely change the sound and structure. Every component must be exact to not mess with the beautiful casing and music that is produced by a musical instrument, whether it’s a violin, drum, or guitar.

For this reason, it was difficult to mass-produce instruments to the degree they are now with CNC machine technology. Manufacturers can create large quantities of high-quality products without sacrificing performance. CNC machine instruments are years away from becoming mainstream, but they can produce impressive results for the client.

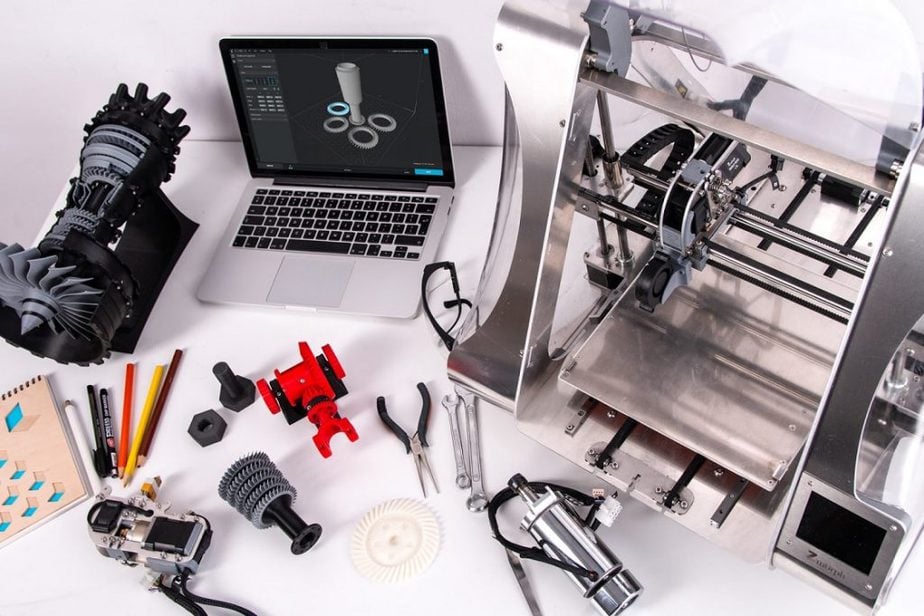

Prototyping

Prototyping is common in multiple industries because it provides a physical item for the client to look at. For example, toy manufacturers will send a prototype to their clients before mass-producing the product to ensure all specifications are correct. It’s common for prototyping to take days, weeks, or months – but that’s now a thing of the past.

Thanks to CNC machines, you can create a digital design within hours and use the machinery to produce a finished product in a short space of time. It will take fewer man-hours to send a prototype to their client, saving thousands in the process. Now, businesses can create their products sooner with improved accuracy.

Furniture and Cabinet Making

Woodworking is a skill all-to-itself that takes years to perfect. While many will still appreciate a man-made couch, chair, or kitchen, there is a lot of use for CNC machining in efficiency. A CNC router can produce a large quantity of furniture without sacrificing the design or material; they are perfect at creating all kinds of household items.

You can personally tailor furniture such as dining sets, beds, staircases, railings, chairs, and furniture from a wide variety of time-periods and places. On top of that, a CNC machine can give your entire kitchen a makeover by crafting side panels, shelves, dados, drawer fronts, and custom doors.

Components for Brass and Aluminium Machines

The coolest thing about a CNC machine is that it can create itself because of its application with hard metals. Working with non-ferrous metals like brass and aluminum has always been challenging because it requires an increased cutting capability, more attention to detail, and a lot of preparation – something the CNC machine can do in strides.

Due to the way most metal is made, whether by earth or by hand, it needs something strong enough to break through its core without splitting or breaking the metal off entirely. For that reason, CNC machines are perfect for creating small metal components useful in cars, forklifts, homes, and power tools.