The type of product to be created and the market opportunity define the best production technique. When you’ve opted to manufacture a product, the first thing you need to do is settle on a manufacturing method. Most employers make the mistake of thinking about the production process after the planning stage is over.

However, they should think about the manufacturing process from the beginning of the design process, rendering it more cost-effective and more straightforward to produce. Some considerations to think about when deciding on a production process for your product are listed below.

Accuracy

The precision of 3D printing is typically around 0.005 depending on the object’s geometry “, regardless of technological advancements. Numerous difficulties depend on part alignments, material, and innovation constantly evolving, but 0.005 is one of them. As a general rule, it is a reasonable quantity.

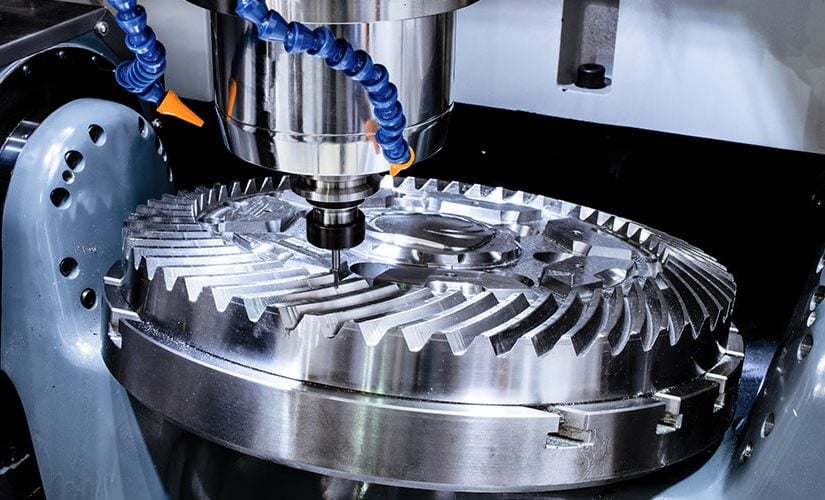

If your part demands precision better than 0.005”, CNC machining service can be the most satisfactory solution. You could also 3D print the model and then use a CNC machine to complete it. That’s more work, and no one wants to squander time on things they shouldn’t have to do.

The Complexity of geometry.

Some forms are impossible to construct using CNC machining. This is the situation because CNC cutting equipment comes into contact with the object from the top.

It cannot reach all sides of the part without turning it, resulting in increased processing and labor time, which is an issue for most firms. CNC machines, for example, make it harder to make hidden features and undercuts. When complex geometry is needed, additive production techniques such as 3D printing may be more suitable.

Time to market

For businesses, lead time is more critical than material appropriateness, geometry, or minimal component size. So, 3D printers vs. CNC machines: which is significantly quicker? 3D printing is usually the better option when a rapid reaction time is one of your goals.

3D printed parts can be created in just a few days. These printers also eliminate the need for tooling changes when creating a new edition of a design or product, shortening lead times.

CNC machining might be a faster method overall when making a larger batch. This is because CNC aluminum parts, unlike 3D printed parts, do not need any post-processing.

If you create more than a hundred similar goods, CNC machining has a substantial advantage in terms of lead time. Once programmed, CNC machines can run unattended for a continuous period. Consequently, for products with more than 100 components, CNC machining can be faster and more reliable than 3D printing.

Bottom Line

Both 3D printing and CNC machining have advantages that make them suitable for a wide range of applications. There is no such thing as universal manufacturing technology, though.

The result will determine the ideal technique for you. Ultimately, those mentioned above and evaluated elements will aid you in making the most outstanding selection possible that is tailored to your company’s needs.