Amid the swiftly changing domain of fabrication, a duo of noteworthy approaches has emerged as contenders in the pursuit of crafting automobile components with efficacy and proficiency: 3D printing through build to print services and injection molding. Every method presents its own distinct array of merits and deliberations.

Within this composition, we shall embark on an exploration into the fundamental principles underpinning both 3D printing and injection molding. We shall also delve into the exclusive advantages they furnish to the production of automotive parts. Ultimately, we shall undertake a comprehensive evaluation of their appropriateness across diverse dimensions.

In the fabrication of automotive components, the selection of an appropriate manufacturing technique plays a pivotal role in dictating the caliber, expenses, and effectiveness. Injection molding and 3D printing have ushered in a transformative era within this realm, each presenting its own distinct merits and drawbacks.

Basics of 3D Printing and Injection Molding

What is 3D printing?

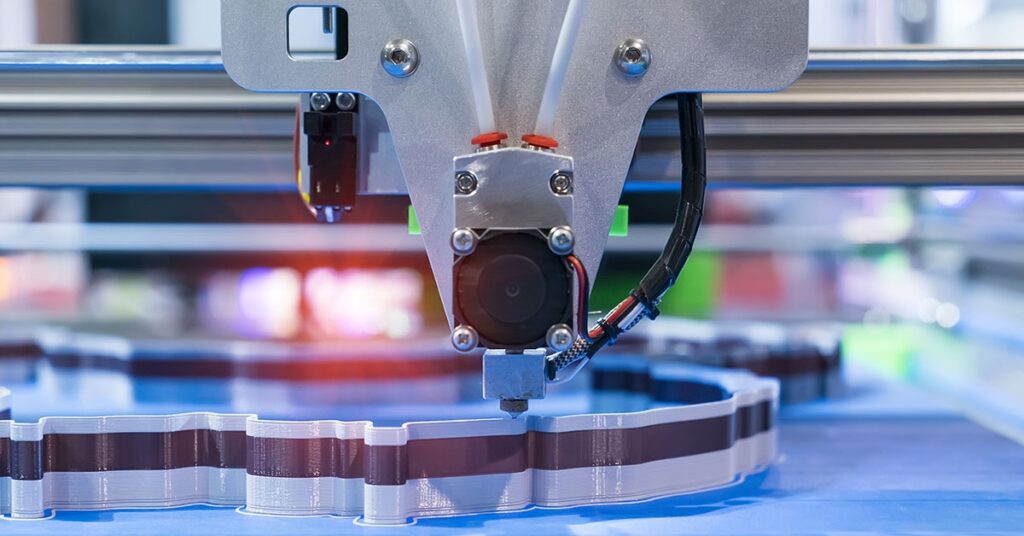

3D printing, often referred to as additive fabrication, is a groundbreaking technique that transforms digital designs into tangible objects through a precise layer-by-layer application of the material. This innovative approach, now enhanced with online 3D printing capabilities, stands in contrast to traditional subtractive manufacturing methods, which involve chipping away at a larger solid piece.

Where conventional methods meet limitations, the versatility of online 3D printing shines through. It constructs objects layer by layer, employing a vast array of materials ranging from plastics and metals to ceramics and even edible items. As a result, designers and engineers are endowed with unparalleled freedom.

What’s Injection Molding?

Injection molding stands as a refined method in the realm of manufacturing. In this process, molten material is carefully injected into a mold cavity, taking on the intended shape once it solidifies. Owing to its ability to achieve unmatched precision and consistent results, custom injection molding has enhanced this method, becoming the preferred choice for mass-producing intricate parts on a large scale.

This specialized adaptation of injection molding caters to specific and distinctive needs. Molds are meticulously crafted, and conditions are fine-tuned to yield components of custom shapes, sizes, and functionalities. This tailored approach addresses the unique demands of clients, offering personalized solutions that conventional mass production avenues might not accommodate.

Advantages of 3D Printing for Automotive Component Manufacturing

3D printing offers numerous benefits to consider, especially within the domain of manufacturing automobile components:

Intricate Shapes: 3D printing facilitates the formation of highly complex patterns that might prove challenging or even unattainable through conventional techniques like injection molding.

Swift Prototyping: This method allows for rapid cycles of prototypes and alterations to designs, rendering it well-suited for the creation and evaluation of diverse renditions of car parts.

Economical Startup Expenses: Initiating a 3D printing operation entails a lower initial capital outlay in comparison to injection molding, presenting an economically viable choice for modest-scale production.

Advantages of Injection Molding for Auto Parts Production

Injection molding offers its own array of benefits:

High-Volume Manufacturing: Because injection molding is built for high-volume manufacturing, it is a practical option when producing many identical auto parts in a short amount of time.

Material Variety: A wide range of materials, including different plastics, metals, and composites, are supported by injection molding, providing greater material selection flexibility.

Surface Finish and Detail: Parts produced through injection molding often have smoother surfaces and finer details, making them suitable for applications where aesthetics matter.

Comparing Their Suitability for Auto Parts Production

Cost Implications

3D printing is advantageous for small production runs, as it eliminates the need for costly molds. However, for larger production volumes, injection molding’s ability to produce parts at a lower per-unit cost makes it the more economical choice.

Production Speed and Volume

Injection molding excel in high-volume production due to its faster cycle times and the ability to produce multiple parts simultaneously. Online 3D printing, while versatile, can be slower and may not be as efficient for large quantities.

Material Performance and Durability

Injection molding offers better material performance and durability due to its ability to use a wider range of materials and achieve higher structural integrity. 3D printed parts might have limitations in terms of material properties.

Design Flexibility and Customization

3D printing shine in terms of design flexibility and customization. It allows for rapid design changes and adaptations, making it ideal for creating prototypes and highly customized parts. Injection molding, while less flexible in design changes, is exceptional for mass-producing uniform parts.

Conclusion

The ongoing discourse surrounding the choice between 3D printing and injection molding for the fabrication of automotive components underscores the absence of a universally applicable solution.

Both approaches possess inherent merits and limitations, rendering them apt for distinct contexts. In the final analysis, the decision hinges upon variables like production magnitude, material prerequisites, intricacy of design, and financial constraints.

FAQs

Which approach proves more economical for producing limited batches?

For manufacturing in smaller quantities, 3D printing often demonstrates greater cost efficiency owing to reduced initial setup expenditures and the nonexistence of high-priced molds.

Can injection molding produce highly complex designs?

While injection molding is limited by mold design, it can still produce intricate designs with smooth surfaces and fine details.

Are 3D-printed auto parts as durable as injection-molded parts?

In general, injection-molded parts tend to be more durable and have better material performance, especially for demanding applications.

Which method is better for rapid design changes and customization?

3D printing is superior when it comes to rapid design changes and customization, making it an ideal choice for prototyping and creating unique parts.