When you need to test whether something is working, be it software, application, or a piece of machinery, you will develop a prototype. A prototype is a smaller, working version of your actual software or machinery.

Designers and manufacturers can quickly discover and substantiate their million-dollar ideas. Rapid prototyping in digital design comes in as a fast and cost-friendly method of animating and building a working component of your product. Rapid prototyping has spanned different areas including architecture.

Types of Rapid Prototyping

Fused Filament Fabrication/ Fused Deposition Modeling

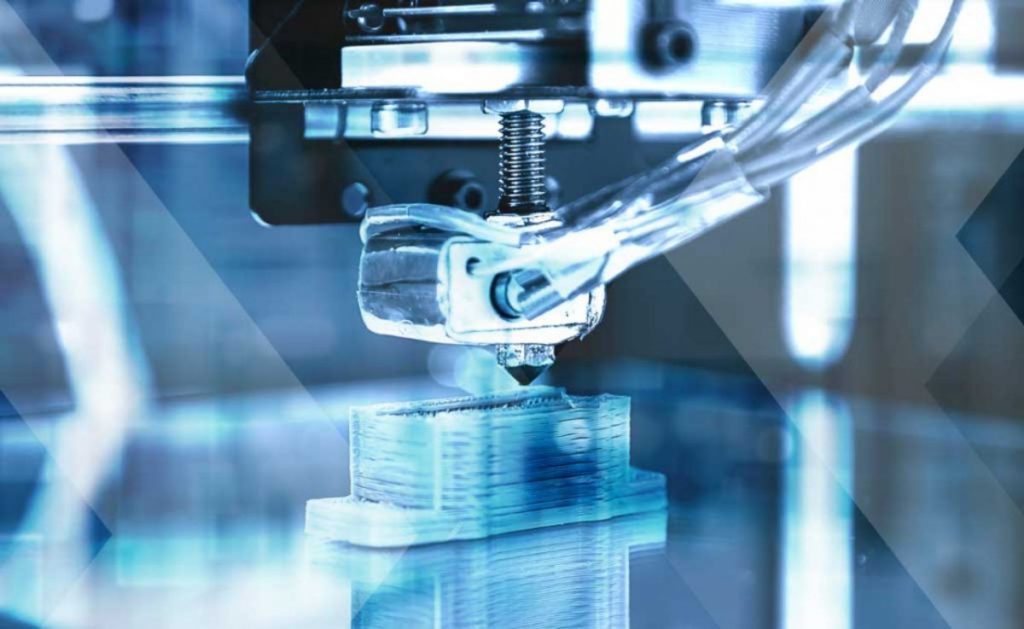

Fused filament fabrication is a type of 3D manufacturing used to create working components of a prototype. It lays molten plastic in layers.

With the assistance of computer-aided designs and software, the molten plastic makes the final product with the technological aid of a 3D printing machine. The machine works layer by layer until the product is finished. The molten plastic dries on the spot.

Plastic and its polymers are one of the most common materials used in a 3D printer, but other materials may be used. Materials such as:

- High-density polyethylene

- Polylactic acid

- High impact polystyrene

Fused filament printing is now one of the most popular methods of printing. Some applications of fused deposition modeling include:

- Commercial applications (medical grade engineering applications)

- Free applications (home use, DIY projects)

3D Printing and Additive Manufacturing

This is the manufacturing of a 3D model with the aid of computer-aided designs. 3D printing involves a variety of processes as well as a wide selection of materials, not just plastic, but metal and ceramics. 3D printing has the capacity to print complicated shapes that cannot be done by hand.

It works by reading specifications on computer-aided design software and replicating the product. There are different categories of 3D printing, such as material and binder jetting, sheet lamination, and powder bed fusion, among others.

Applications of 3D printing include:

- Prototyping (for presentation models and assembly mockups)

- Lightweight parts (for automotive and aerospace applications)

- Functionally enhanced products (footwear)

- Custom medical implants (titanium implants and prosthetics)

- Tooling, jigs, and features (screwdrivers)

- Metal casting patterns (large metal objects)

Laminated Resin Printing

Laminated resin printing is used to create and prototype high-resolution microscale structures. Microstructures are produced using complicated techniques. This type of printing makes it easier and faster to produce sensors, electronics, and wearables.

It comes in handy for researchers, developers, and manufacturers. Laminated resin can be used in the following ways:

- Printing on different types of substrates such as silicon, paper, and printed circuit boards.

- Printing multi-layer and single-layer structures commonly used in microfabrication. (fabrication of miniature structures)

- Producing prints with extreme thermal and chemical resistance.

- Rapid prototyping where size and weight matter. (Surgical instruments)

Laminated resin printing is:

- Easy and affordable to use.

- Scalable from the prototype to the production and uses the same material.

- Offers fast imaging speeds.

- Does not require a cleanroom.

- It is ideal for microsensors.

Solid Ground Curing

This is a method of the 3D printing technique that delivers models, model parts, and creation parts. It is a photopolymer based additive type of mass production. A high-powered UV lamp is exposed to each layer of the polymer as the basis of solid ground curing.

The culmination of solid ground curing is to ensure each layer is cured simultaneously. This does away with the need for post-curing processes.

Some of the advantages and disadvantages of using this method for production include: It offers a quantifiable level of dimensional accuracy as well as high throughput. However, it is also an expensive process due to the high complexity and acquisition process. It also produces too much waste, but the volume of production is also big. Solid ground curing is the ideal technology for short production operations.

Selective Laser Sintering

Selective laser sintering is a type of powder bed fusion, where powder polymer, metal, or resin is partially positioned under a laser. This, in turn, concludes in a hardened solid structure or layer. The materials used in selective laser sintering include:

- Polycarbonate

- Polystyrenes

- Semi-crystalline thermoplastic Polyamides

This method of 3D printing is used in the manufacturing and production of end-user parts in the military, automotive, medical, and aerospace and electronics. It has also found use in art.

Some of the advantages of using this method of building 3D rapid prototypes include:

- It is one of the fastest methods of producing functional prototypes and end-user parts with durability.

- Has good resistance to chemicals.

- Has reliable mechanical properties with high strength and stiffness.

- It has multiple finishing capabilities such as tub coloring, coating, and metallization, and flocking, among others.

- It can build complex parts with interior components without trapping any material inside.

- It can accommodate a wide array of materials with characteristics of strength, functionality as well as durability.

Some of the misgivings of using this method in production include:

- Parts have porous surfaces.

- It is not suited for personal or residential use.

- It is a long process that requires bulky and expensive materials as well as a laser.

In general, rapid prototyping is safer because you can always have backup ideas, and it is easier and cost-effective to test your concepts. It is also quicker to develop prototypes and manufacture end-use parts, making it very timesaving. Not to mention, it is an enjoyable activity to develop your own prototypes on a 3D printer. You do not even need to be a tech guru to be able to own or work on a 3D printer.

Get Your Prototypes Printed Quickly

We have already stated the benefits of using each printing model mentioned above. The reliability and cost-effectiveness alone should be a definite selling point. All in all, 3D printing is the future. And the future is here!

Southern model is a company that specializes in building 3D architectural modelling using the latest technology. With great service and a great product, it is a no brainer; you must try their services. With the collaboration between different technologies, your idea or architectural project will come to life at Southern Model.