Modern technology does not stand still and now in our everyday world, such a concept as 3D printing has become firmly entrenched. In general, 3D printing itself was invented by Charles Hull and appeared back in 1984. Now, 3D printing technology has become so popular and extensive that the task of creating a part or model can be realized not only in a large enterprise but also in your home, and all thanks to the fact that it has materials such as polymer binder which are indespensible for these type of projects.

3D printing technology itself is a sequential implementation of actions that will lead to the creation of a product, namely:

First, a 3D model is created on a computer using special programs for 3D modeling, and it can be created on the basis of drawings or using a 3D scanner.

Next, the created model must be saved in the STL file format. After the STL file is loaded into another slicer program, where the print layers are formed and the remaining settings are configured.

Now save in gcode file format (note, some printer’s support their own code formats).

The last stage is the creation of a product on a 3D printer using the gcode-file loaded into it. The printing technology on all 3D printers is almost the same.

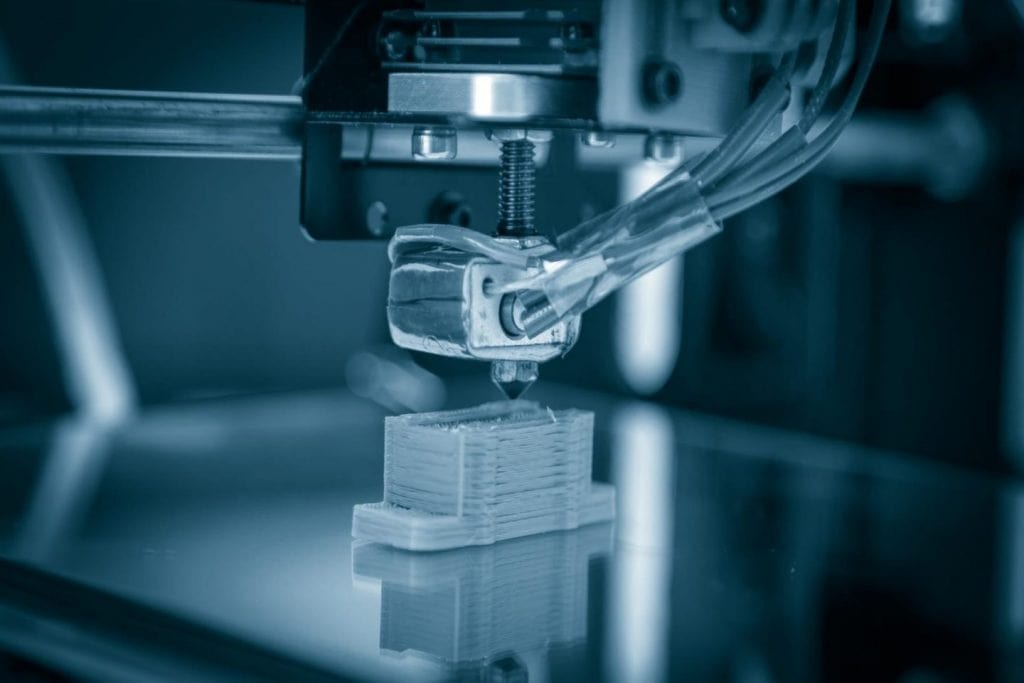

The printing process proceeds according to the principle of applying (preheated material to a semi-liquid state) the material on the first – lower layer, and then the extruder performs cyclic movements (along the paths created on the computer) along the guides layer by layer forms the product, each subsequent layer is superimposed on the previous one.

TYPES OF 3D PRINTING.

- Fused deposition modeling (FDM)

Additive manufacturing technology, which is now the most widely and actively used to create three-dimensional models.

It makes it possible to create not only models but also end parts from standard, structural and highly efficient thermoplastics, like Perspex. This is the only technology using industrial-grade thermoplastics, providing parts that have no analogs in the mechanical, thermal and chemical properties. Also, with this printing technology, the use of soluble auxiliary materials is possible, which allows creating complex multi-level forms, holes and overhanging elements that would be problematic to obtain using conventional methods.

Technology Advantages:

- Durable wear-resistant products;

- Low cost of materials;

- Extensive post-processing capabilities.

Disadvantages:

- Low resolution both horizontally and vertically;

- Problems with fixing the model on the desktop;

- Overhanging elements require the creation of supporting structures, which subsequently have to be removed;

- Low speed.

- Digital Light Processing (DLP)

The additive manufacturing method, a variant of stereolithographic 3D printing. The method is based on the use of photopolymer resins that harden when irradiated with ultraviolet light. However, an alternative method uses digital LED projectors (DLP), which helps reduce the cost of devices. Unlike laser installations that scan the surface of a material with one or more laser heads, DLP printers project an image of a whole layer before the polymer resin hardens, after which a new layer of material is applied and an image of a new layer of a digital model is projected.

Such printers are used in dentistry, jewelry industry, mechanical engineering, as well as in the design and manufacture of souvenirs.

Technology Advantages:

- High printing accuracy with a minimum layer thickness;

- The use of various materials from hard plastics to rubber;

- Low cost of consumables.

Disadvantages:

- Printing in one color, but there are no palette restrictions;

- Slow print speed.

- Metal Powder Sintering (EBM)

The technology uses electron beam melting to create three-dimensional objects. For layer-by-layer deposition of high-precision parts, a special material was developed – metal clay (metal powder). This material is made from a mixture of organic glue, metal chips, and water.

To date, only industrial printers are sold. Their profile is in the aerospace, defense, and automotive sectors, in medicine to create prostheses and implants.

Technology Advantages:

- High print quality;

- Excellent drawing of small details;

- Electronic pulses instead of a laser beam;

- High-speed printing;

- Parts obtained by this technology have a better microstructure than those made by casting;

- Possibility of producing several products at once.

Disadvantages:

- At the moment, electron beam melting is limited to an accuracy of 0.2 mm, due to the size of the electron beam, which is 0.2-1.0 mm. This leads to a slight roughness of the finished product. Check out Pick3DPrinter’s list to learn more about The Best Metal 3D Printers.

- Selective laser sintering (SLS)

Additive production method. The technology uses a high power laser to sinter small particles of plastic, ceramic, glass flour, or metal into a three-dimensional structure.

The main feature of this technology is the use of powders consisting of metal particles coated with a polymer. After the sintering process, the part is placed in a high-temperature furnace, where the plastic burns out, and fusible bronze takes its place.

The operation of such SLS printers is not possible at home, because they are large and expensive because the sintering process takes place in a vacuum or inert environment.

Technology Advantages:

- No need for support materials. The part is immersed in powder, which performs the function of supporting overhanging parts;

- Large selection of materials, including metals;

- High print speed (up to 35 mm / hour).

Disadvantages:

- The rough structure of models requiring further processing;

- Long-time to prepare the printer for work (heating and temperature stabilization);

- The inability to print metal at home.

- PolyJet

3D printing technology based on layer-by-layer curing of liquid photopolymer material under the influence of ultraviolet radiation. Used in Objet 3D printers.

The 3D printing unit in thin layers (16/30 μm) sprays the model material and the support material according to the mathematical 3D model. Each layer is polymerized by the light of an ultraviolet lamp immediately after application. The result is an object that does not require any additional surface treatment. A model printed using PolyJet technology can be used directly after the printing process is completed, such models have different properties – depending on the material used. Materials differ in mechanical, thermal, electrical and chemical characteristics.

Technology Advantages:

- Smooth surface of finished products;

- Excellent physical and mechanical properties of prototypes (including geometric stability);

- Possibility of surface treatment (gluing, painting, etc.).

Disadvantages:

- High unit cost of 3D printing.