Threads are important features of many products used to form coupling between two different entities. This coupling has many advantages and functions. A perfect example of threading is the inner threading of the water bottle cap and the external threading on the bottle top. The bottle cap couples with the top of the bottle by coupling using the internal and external threads.

There are many thread machining methods you can use. However, one very unique process is thread milling delivered by many CNC milling services such as RapidDirect. To understand why thread milling should be your thread machining process, this article will discuss what thread milling is and how it works. It will also introduce other thread machining methods and why thread milling should be the right method. Read on!

What is Thread Milling?

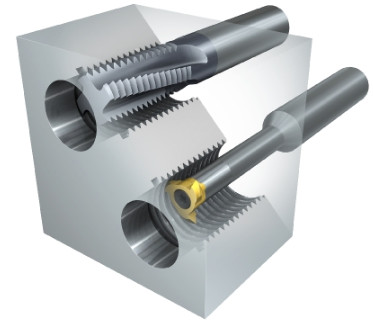

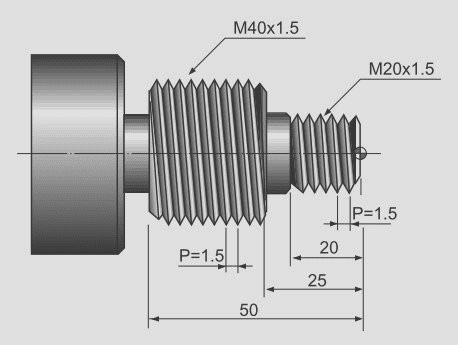

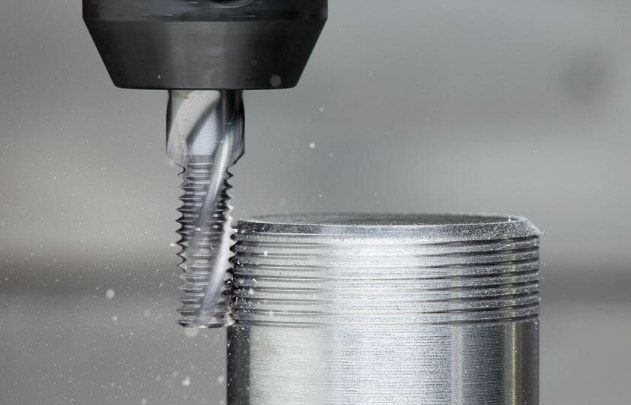

Thread milling is a CNC milling process that involves cutting threads of different sizes on objects using a thread milling cutter. It is a high-quality threading process suitable for holes with large diameters.

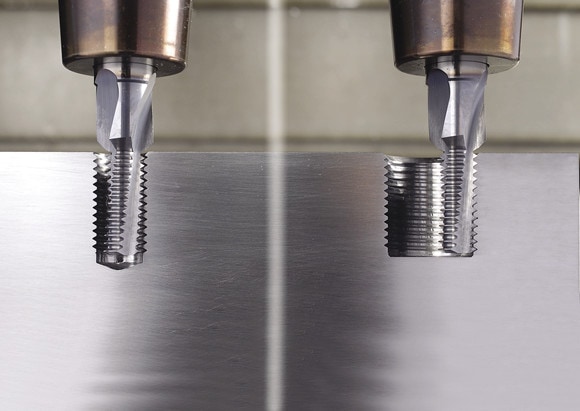

Thread milling is achieved using solid carbide or indexable insert thread mills. Both thread mills can produce threads of high accuracy and surface finish.

- Solid Carbide Thread Mill

This thread mill is more suitable for making threads on holes of small size. However, it is cost-effective when there is a need for quality threading.

- Indexable Insert Thread Mill

The indexable insert thread mill does not fit in holes with diameters equal to or less than 0.625 inches. Therefore, it is more suitable for larger holes.

Both types of thread mills are primarily applied to large workpieces. However, solid carbide thread mills are also applicable for threading small holes, left and right-hand threads, different thread tolerances, and different materials.

Thread Machining Methods Overview

Thread milling is a popular thread machining method that can produce high-quality threads. However, there are other machining methods you can use. Below are the common thread machining methods available industrially.

-

Thread Rolling

Thread rolling is an economical, fast, and cold working process that uses flat or circular dies for threading. The cold rolling process strengthens the thread in tension, shear and fatigue. It also leads to a good surface finish.

While thread rolling is very fast, it is not as precise when compared to thread milling. It is confined to parts with a need for only external threading as it is not easy to perform internal threading. Thread rolling is applicable in an electric light bulb, wood screws, machines, cap screws, etc.

-

Thread Chasing

Thread chasing involves threading using a lathe chasing tool. It is a slow threading process as only little material is removed per rotation. Even though material removal is slow, the removal can still be minutely controlled and adjusted. Consequently, thread chasing is the right method for threading worn parts. It is also ideal for square threading and internal/external/concentric threading.

-

Die Cutting

Die-cutting is the most common external threading process. It is fast and economical with moderate quality and accuracy. Therefore, it is an acceptable threading process for mass-produced articles. There are two general types of die you can use:

- Bottom or Round Split Dies

These dies are normally for hand use. However, they are usable by machines also. They have a round shape, and radial cuts close by a screw. Consequently, they are adjustable.

- Adjustable Dies

These are two pieces held in a collet or mounted directly on the die stop. They are primarily intended for hand use.

-

Tapping

Tapping is another machining method for making threads, and they are applicable for internal threading. A tap is similar to a screw with teeth made up of hard material and ideal for cutting metals. The teeth are formed by the flutes which also act as the channel for carrying away the chips formed during threading. There are many taps:

- Hand taps and machine taps

- Straight shank and bent shank taps

- Regular pipe taps and interrupted thread pipe taps

- Solid taps and collapsible taps.

-

Grinding

Grinding is ideal for making internal or external threads. Threading occurs as the grinding wheel rotates. Grinding is one of the most accurate threading machining processes, together with thread rolling and thread milling. It eliminates tiny cracks due to hardening and distortion due to heat treatment. There are two grinding methods:

- Pass Over or Traverse Method

Here the grinding wheel is positioned at full thread depth with the work being traversed past it. A master lead-screw controls the traversing process. Also, change gears are used to alter the pitch.

- Plunge Method

In the plunge method, instead of traversing, the grinding wheel is plunged into the work to full thread depth. The workpiece will then make a revolution that results in one pitch.

Why Use Thread Milling?

Thread milling is an ideal thread machining method due to the different advantages it offers. Below are the advantages that thread milling offers:

-

Better Thread Quality

Thread milling can deliver better quality than other threading procedures such as tapping, die-cutting, and rolling. For example, the quality of threading milling is higher than tapping because milling offers better chip evacuation.

-

Flexible Tool

Thread milling boasts flexible tools and secure machining operation. Therefore, you can use the tool to thread materials of different diameters. Also, the tools have minimal risk for machining because the thread mill diameter is lesser than the thread. Therefore, if there is tool failure, there is less tendency for the workpiece to be damaged.

-

Threading In Difficult to Machine Materials

Thread milling is compatible with many materials. Many machining methods cannot thread hard materials. However, thread milling is compatible with difficult materials such as hardened steel up to HRC 65 and Titanium.

-

Threading In Blind Holes

Thread milling is also applicable in threading blind holes. The machining process can produce a complete thread profile hole, unlike other methods such as tapping which makes a complete thread profile on the third thread.

Thread Milling Services with RapidDirect

Threading is an important process in many industries. Therefore, the right knowledge of thread machining methods is indispensable. If all you need is to get the job done using a company that delivers quality thread milling service, you can take RapidDirect into consideration.

Considering their years of expertise in CNC milling services and top-notch customer satisfaction makes them one of China’s superior online rapid prototyping service providers.You can expect to get a successful result with them.