The modern electronics and computing revolution began with the invention of semiconductor devices and integrated circuits during the 1950s. Since then, electronics technology has advanced by leaps and bounds. Not only the design complexity is increasing but the device sizes are also shrinking continuously. The demand for lightweight electronic devices and the availability of miniature electronic components require advanced manufacturing techniques and methods.

In any electronic equipment, printed circuit board (PCB) is a crucial component as it holds and interconnects all the electronic components together. The primary function of a PCB is to provide mechanical stability and electrical connections. The electronic components are soldered on the PCB using various techniques. Professional PCB designing and component soldering is a complex procedure with multiple process steps and should be handled only by qualified professionals.

What is SMT assembly?

When it comes to soldering components on a PCB, there exist two main technologies which are through-hole technology and surface-mount technology (SMT).

Through-hole technology was primarily used in older circuits when SMT was unavailable and nowadays is only used in amateur and hobbyist circuits. The through-hole soldering process involves the drilling of holes in the PCB, mounting electronic components on the PCB and soldering the component leads to the copper traces on the opposite side of the board. This soldering process is costly, slow, cumbersome, and cannot be automated. Moreover, the components with lead terminals tend to be bigger in size and therefore are unsuitable for modern electronic circuits with strict form factor requirements.

Today surface mount soldering has completely taken over the traditional soldering methods in professional PCB manufacturing. In surface mount soldering, components are directly placed on the PCB surface rather than through the drilled holes. The surface mount devices (SMDs) exhibit far smaller footprints than traditional components. Due to this reason, a large number of SMD components can be packed into a smaller area which results in a very compact and sophisticated electronic circuit design. Another great advantage of SMT assembly is that the process can be automated which results in to increased accuracy, speed, efficiency and cost efficacy. Due to all these benefits, today SMT assembly is the default method of soldering in the electronics manufacturing industries world over.

Surface mount devices

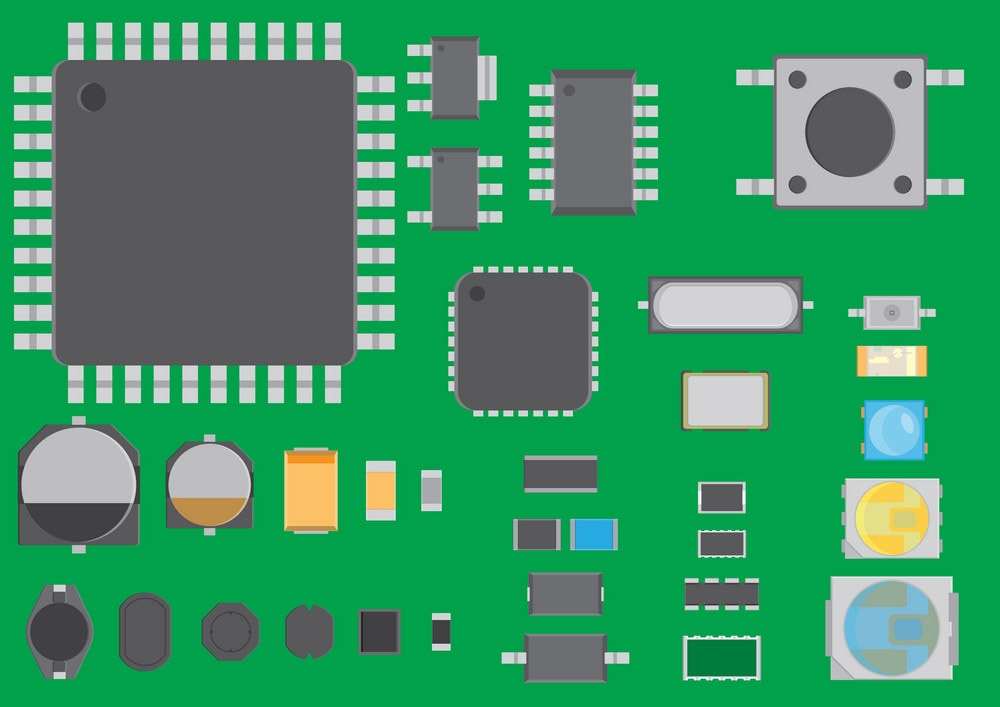

Traditional electronic components with lead terminals cannot be used in surface mount soldering. Hence, specialized component packages are required which are known as surface mount devices or SMDs. A small footprint is the distinctive feature of all SMD components. These components are designed to sit directly on the PCB surface rather than penetrating the board. SMDs can be broadly classified into three main categories:

- Passive components

- Discrete semiconductor devices

- Integrated circuits

Passive components include resistors, capacitors and inductors. The SMD passive components are available in multiple standardized sizes. The electrical connections with the PCB are made using the metallic contacts present underneath the SMD device package.

The second category of SMD devices includes discrete solid state components such as diodes and transistors. These devices are commonly packaged in plastic packages with protruding lead terminals. These terminals sit directly on the PCB and are soldered on to the board’s surface.

There are hundreds of thousands of different types of integrated circuits in existence. Due to the varied nature of ICs, a number of different packaging standards are used for SMD ICs. Smaller chips like regulators might only feature 3 or 4 pins whereas complex chips like FPGAs and SOCs might have hundreds of terminals. Some common packages used for smaller chips include SOIC (Small Outline Integrated Circuit), TSOP (Thin Small Outline Package), and SSOP (Shrink Small Outline Package). On the contrary, the bigger and more complex chips usually use QFP (Quad Flat Package) standard. The QFP package has a square/rectangular shape with pins protruding out from all four sides.

Advantages of SMT assembly

Surface mount soldering offers many advantages over the older through-hole technology. Some of the salient advantages include:

- Compact size and denser circuits

- Low power consumption

- Improved EMC design

- Faster assembling and mass production

- Increased cost efficacy

The SMD components are inherently smaller in size than through-hole components. This results in compact and densely packed circuits. The increasing demand for lightweight portable and wearable electronic devices forces the engineers to come up with very compact circuit designs. Hence, in modern consumer electronic devices, SMT assembly is the only way forward to ensure high-performance, high-density circuit design.

Virtually all the modern portable and wearable consumer electronic devices are battery powered. In order to provide optimal battery timing to the end user, low power consumption and efficient power management are absolutely crucial in such applications. Due to their smaller footprint and advanced design, SMD components tend to have lesser power ratings than their counterparts which results in power efficient circuit design.

From the manufacturing point of view, the biggest advantages of the SMT assembly are the low cost and automation. The automated soldering and PCB assembling process ensures mass production with very high accuracy and reliability. The smaller form factor of the SMD components makes them more cost-effective than through-hole components. These factors make the SMT ideal for mass production.

Another advantage of SMT assembled circuits is the reduced parasitic capacitances and inductances due to the smaller component size. This has a direct impact on the EMC (Electromagnetic Compatibility) of the circuit. Consumer and commercial electronic products need to fulfill the EMC standardization in order to be marketable in the international market. Hence, SMT assembly provides an added advantage of reduced EMI.

Handing over surface mount soldering to professionals

There is no doubt that SMT has an overwhelming number of advantages however the process is far from simple. In fact, professional SMT assembly is a complex process which involves multiple process steps. Keeping in mind the complexity of the process and the required level of expertise, the SMT assembly work must be performed by trained professionals. Following points justify the handing over of the SMT assembling work to the professionals:

- Specialized tools and machines

- Component sourcing

- Skill and expertise

The tools and machines required for SMT assembly are often quite expensive. It is quite difficult for a novice to setup a proper lab with all the required tools and machines as it can cost a fortune. However, professional SMT assembly companies like PS Electronics, have proper setup with all the required equipment. Therefore, outsourcing the SMT assembly jobs makes the workflow easier, straightforward and cost-effective.

Apart from the availability of tools and machines, professional skills and expertise are equally important. Without proper expertise, machines are good for nothing. SMT assembly is a complex process and requires a lot of dedication and practice to master. Hence, it is far more efficient and effective to hand over the assembly task to the professionals rather than reinventing the wheel on your own.

Apart from tools and expertise, the SMT assembling companies like PS Electronics, can source the components much more easily and effectively as compared to an inexperienced person or organization. The companies with expertise in surface mount soldering also specialize in component sourcing which enables them to source the components much faster and much cheaper.

The SMT market was valued at 3.24 Billion USD in 2016 and is geared for a growth rate of 8.9% between 2017 and 2022. The SMT market is a huge market with many niches and market segments. The target audience includes IC designers, OEMs, product manufacturers, research and development organizations, system integrators, consulting firms. The growth rate graph of PCB manufacturing can be seen in the following figure.

Since sophisticated electronic circuits and computers are used in each walk of life, hence there is no such sector for which SMT technology is not relevant. Prominent domains include consumer electronics, telecommunications, aerospace and defense, automotive, medical and industrial electronics. The market breakdown by region is presented in the following figure.

In light of the above discussion, it is clear that handing over the SMT soldering and assembly tasks to professional companies, is the only optimal solution that ensures speed, efficiency, quality and cost-efficacy.