It’s impossible to pin down the creation of the electrical motor on a single individual. Throughout history, many investors have tried and tested different methods in relatively short succession. Many of the previous inventions have helped usher in servo motors, including the creation of the battery and the discovery of electromagnetism by Alessandro Volta and Michael Faraday, respectively. However, it is Moritz von Jacobi that is credited with the creation of the first working rotating motor.

Later, in the 1960s, the Yaskawa corporation brought in several innovations in the motor industry, ushering in a new era. Now, several decades later, most factory and warehouse automation solutions use a servo motor. The difference between it and a regular motor is that the latter works by rotating continuously, while the former does the same while also responding accurately to the target, making it the preferable option.

While servo motors have a long history, the simple fact that they are used across several industries makes them susceptible to frequent innovation efforts, meaning that the market still has a lot to show when it comes to what these devices can offer.

The main types

The servo motor is split into two main categories, the AC and the DC. The former is the most common among most companies, fining industrial applications within most fields. They work through a controller-based system, providing closed-loop control and are renowned for their efficiency, accuracy and ability to be easily controllable. The latter, the DC motor, was more common in the past, but it fell out of use within most industries and was gradually replaced by the easier-to-use AC model.

When you’re looking to purchase a servo motor, you have several options to choose from depending on the requirements of your task. There are brushless, permanently magnetised motors with a low cogging torque that support synchronisation even when going at a low rotational speed. They offer reliable and dynamic processing and use digital displacement encoders that are both single and multi-turn.

Use cases

There are several use cases in which servo motors are employed, and with the increase in automation across all industries, their use has become all the more relevant. The importance of these tools comes from the fact that they are used by items that are used on a daily basis, such as Blu-ray players and cars. In the case of the latter, the motor is used to control the speed. Stepping on the gas sends a message directly to the automobile’s computer, signalling that the servo attached to the throttle should amp up the speed of the engine. Larger methods of transport, such as aircrafts, use servos to control elevators and operate grippers, among other uses. The main advantage of the servo is that it packs quite a lot of power for its relatively diminutive size.

The most common use case for these motors comes from the industrial sector, where they power processes in pharmaceutics, robotics and even food services. They are also well-suited for electrically-operated machinery, including robots, rudders and escalators. However, despite these tried-and-tested use cases, there are many innovations occurring within the sphere of items that are relative novelties. These include toys that are remote-controlled such as aeroplanes, helicopters and cars.

Innovations

Despite the fact that servo motors have been around for quite some time, many innovations are still yet to come. Some of them are in the making at the moment. One of the aspects uniting all technological devices is that, as time passes, they tend to become more compact and easier to manoeuvre/ The same applies to servo motors, which will soon get a new, updated generation that makes lighter devices that are also more compact. The change will come from the new generation offering frameless, high-torque tools.

It will come in seven rotor and stator frame sizes, each with three stack lengths and with rated outputs between 200 W and 1.43 kW. They will be designed for operation at a maximum of 48 VDC, with the windings created for torque and speed requirements of 15 kg and 3.5. There are also models with thermal sensors, harmonic gear and accessories meant to improve energy efficiency and provide smoother movements overall.

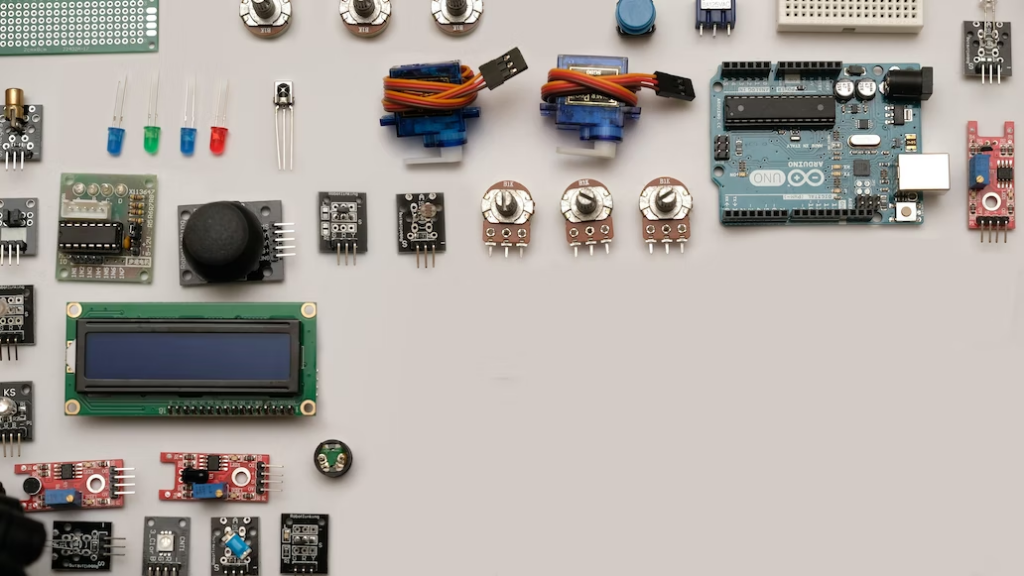

The MIT Student Art Association has also created workshops meant to teach students better skills in the field of motors, as well as start an interdisciplinary approach by addressing their relationship to sensors and wiring through the development of kinetic artworks. This helps improve the learning experience for students who haven’t responded well to traditional engineering and coding training. The students get different items depending on their requirements, with servo motors being the most popular.

Some students have come up with extraordinary designs in some unexpected fields, such as fashion. One of them is a floral evening gown with insertions that open and close continuously. The technique works by attaching a servo motor, which can alternate between 0, 90 and 180 degrees, depending on the case, to the post. There’s no need for a complicated development, as a simple application of wires and glue is enough to hold everything in place, and although rough around the edges, it shows that the project works and can be developed in the future to develop more procedural finesse.

The bottom line

The main advantage of using a servo motor is that it poses virtually no difficulty for companies who use it. They are known to be frequent and able to withstand work at the same pace for an extended period of time. If a heavy load is placed on the motor, the motor oil will be increased to rotate. That means that the engines are constantly expected to be mechanically in tip-top shape. Precision also means that companies can work efficiently at all times and increase speed if necessary. That helps them increase production at consistent rates.

The servo motor has existed for a long time, and as industries develop, its applications show no sign of becoming obsolete. The constant innovations ensure that businesses and factories will be able to use them for a long time in the future.