Finding a reliable electronic component supplier can feel challenging. One wrong move and you risk project delays, subpar components, and mounting costs. With countless options in the market, making an informed decision is crucial.

According to a report by Supply Chain Dive, 73% of businesses encounter disruptions due to unreliable suppliers after the pandemic. This highlights the importance of selecting the right partner to deliver quality, consistency, and trust. Here’s how to approach the process and set your business up for success without unnecessary headaches.

Choosing the Right Supplier; A Step-by-Step Process

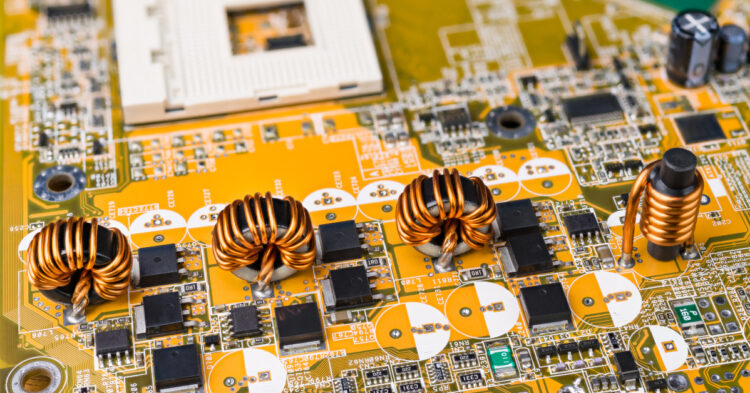

Electronic parts are the foundation of every mechanical development and innovation. From consumer gadgets to critical industrial systems, these parts power everything. A damaged or postponed part can stop production, drain assets, and stain your standing in the market.

Therefore, picking a dependable provider guarantees your inventory network stays consistent, and your items proceed true to form. Here is a step-by-step process to help you out:

Step 1 – Verify the Supplier’s Credibility

Begin by deciding how reliable the supplier is. This is non-debatable. Unwavering quality is a two-way road, and a supplier’s history says a lot. Hence, certifications like ISO 9001 or other applicable industry guidelines that exhibit their adherence to quality practices should be investigated.

You can likewise review and read testimonials from past and current clients. A well-explored supplier frequently follows through on its commitments, and a well-reviewed supplier often delivers on its promises. Suppliers with a long-standing history are less likely to falter. It’s also smart to research their client base. If they supply to big names in the industry, chances are they know how to handle high standards and enormous demands. Trust but verify, as they say.

Step 2 – Assess Product Quality Standards

Quality is the heart of what makes a component supplier reliable. A poor-quality part can lead to massive downstream issues, so you need to vet quality upfront. Here is what you can do to assess product quality standards:

- Request product samples to test for durability, functionality, and adherence to specifications. This helps you identify whether the components meet your needs.

- Cross-check the specifications in datasheets with the actual product performance. Any discrepancies here are red flags.

- Ask if the supplier complies with certifications like RoHS or CE, demonstrating environmental and safety standards.

Suppliers like Fairview Microwave and IPC International exemplify high standards in product quality, making them a benchmark for reliability. Never settle for a supplier who cuts corners on quality because it’s simply not worth the risk.

Step 3 – Evaluate Supply Chain Practices

The supplier’s supply chain practices can make a significant difference in how seamlessly your operations run. A robust and efficient supply chain translates to fewer delays and smoother processes. To evaluate supply chain practices, you can:

- Investigate how they manage their inventory. A supplier that keeps critical components in stock is less likely to cause bottlenecks.

- Ask about their lead times for orders, especially for custom or high-demand parts. Transparency here is essential.

- Understand their contingency plans. How do they handle sudden disruptions like material shortages or shipping delays?

Suppliers that communicate clearly about timelines and contingencies demonstrate reliability. Additionally, check their geographical proximity if timelines are a concern; a supplier closer to your operations may offer quicker deliveries.

Step 4 – Comprehend Pricing and Guarantee Terms

Pricing is often the primary thing individuals consider, but there’s more to a decent deal than numbers on a statement. You should investigate the provider’s cost evaluation and guarantee terms to avoid shocks. This entails doing the following things:

- Compare their pricing against industry benchmarks, but don’t choose the cheapest option. Sometimes, too-good-to-be-true prices come with hidden compromises.

- Confirm their warranty policies. A reputable supplier stands behind their products and provides clear terms for replacements or refunds.

- Review their return process. Will they cover shipping costs for defective parts, or will you be left footing the bill?

A transparent pricing and warranty structure is a sign of a supplier that values their customers. Don’t hesitate to ask for clarification on anything that seems ambiguous. It’s better to clarify sooner rather than regretting it later.

Step 5 – Test Customer Support Quality

Last but not least, the quality of a supplier’s customer support is often a reflection of how much they value their clients. A good supplier provides excellent components and they’re also quick to address any hiccups along the way. Checking the customer support quality is relatively easy with the following tips:

- Reach out with a few questions before committing to a supplier.

- Note how quickly and thoroughly they respond.

- Ask for a direct point of contact, such as an account manager, who can streamline communication for ongoing needs.

- Inquire about after-sales support.

Good customer support is essential. A responsive team can save countless hours and avoid unnecessary frustration when challenges arise.

Final Words

In conclusion, finding a reliable electronic component supplier involves research, vetting, and communication. By following these steps, you ensure your supply chain is built on a solid foundation. A reliable partner will deliver products promptly and ensure your business thrives.